In cooperation with the Fraunhofer Institute for Laser Technology and the laser specialist LightFab, BUSCH conducts research on the possibilities of precision construction through seamless high-resolution 3D printing – in short: PANDA.

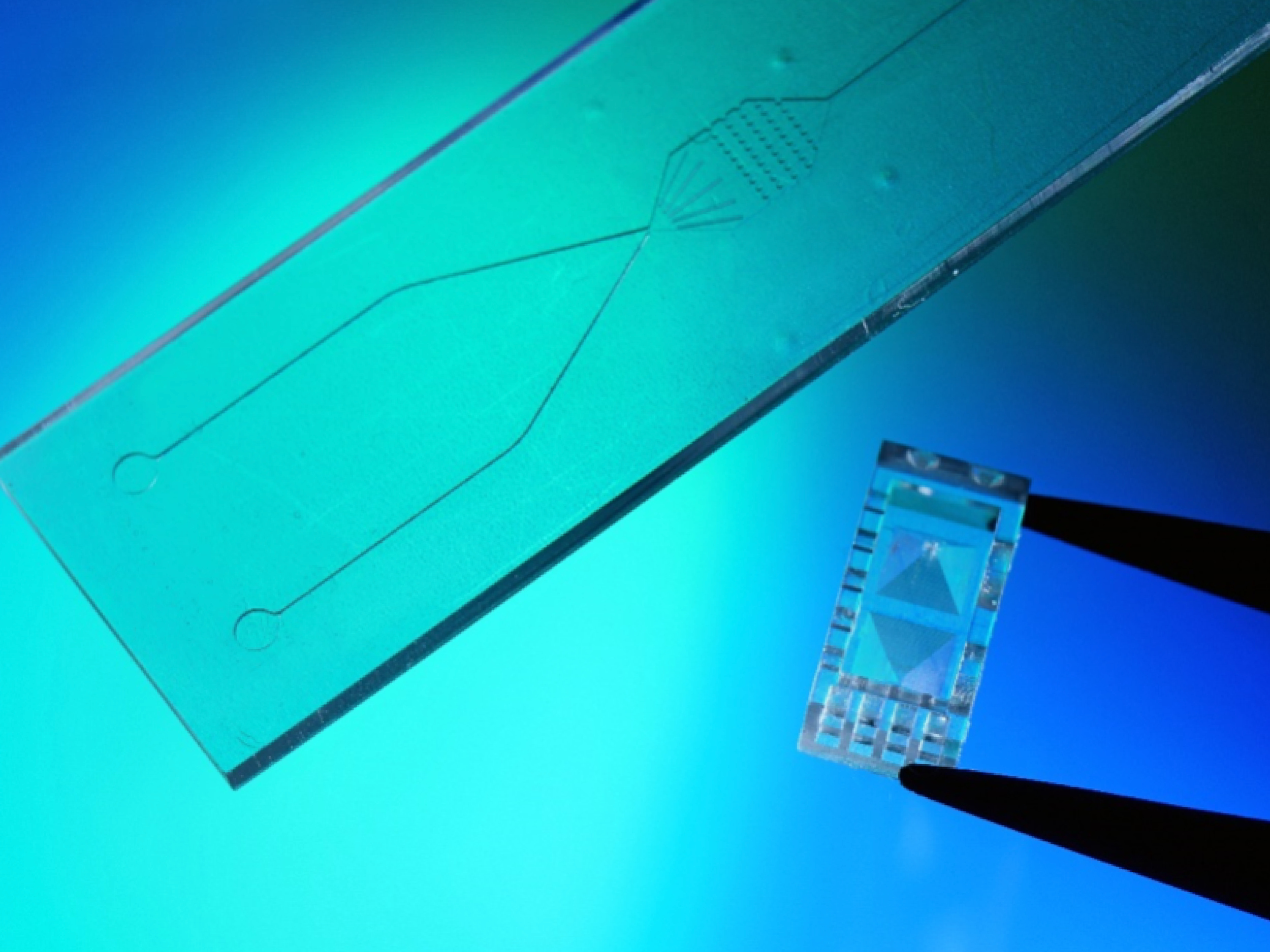

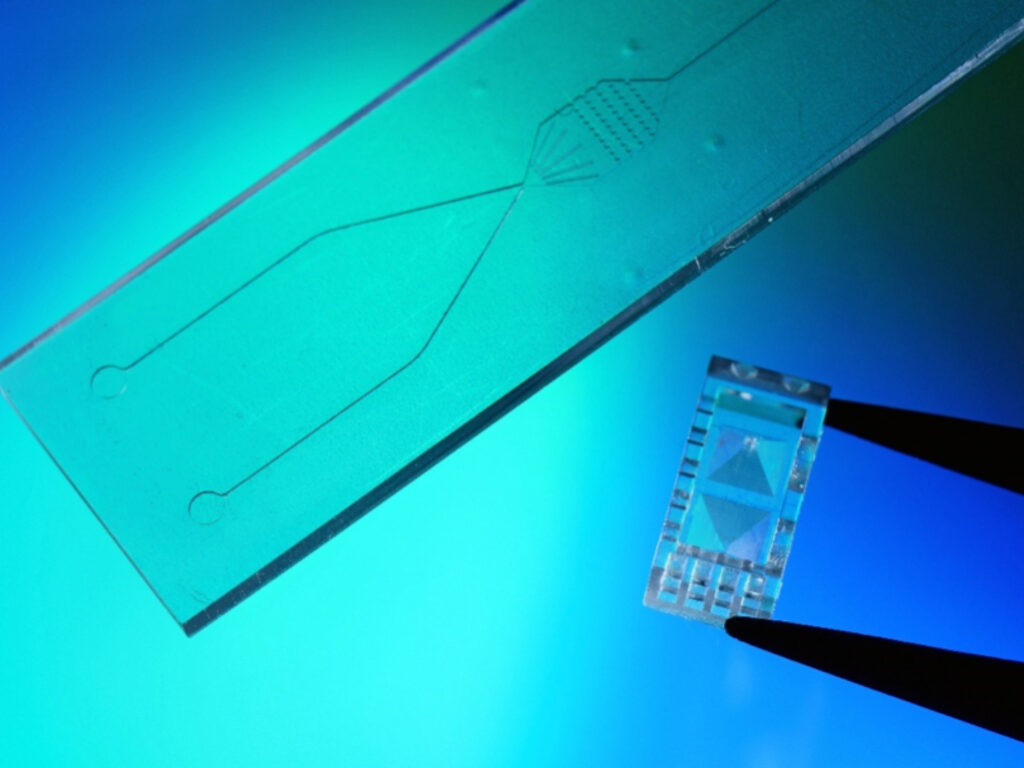

The project emerged out of the requirements of medical diagnostics, where rapid Point-of-Care-Tests are increasingly being used for the most diverse diagnostic assessments instead of lab tests. The microfluidic chips, in which a sample is introduced, have channels in size range of 50 – 200 µm with a surface roughness of a few micrometers. The accuracy and response speed of these tests depends on the controlled, accurate contact of the reagents.

These microfluidic systems are usually manufactured by means of injection molding or hot stamping. However, these methods are not economical for prototypes and small series production that are necessary, for example, for design studies.

In principle, the additive methods such as 3D printing can be used as alternative, which do not require expensive molds or the like, but rather build the object almost in individual production from the design software.

Here the problem is the insufficient resolution of the existing processes. The stereo-lithography achieves the required surface quality. Digital Light Processing can increase the resolution significantly but not sufficiently, as the microfluidic chips require pixel size of less than 10 µm. Currently this can be achieved only if the overall size of the exposed area is rather small, and due to seams or interfaces the juxtaposition of several surfaces results in an inadequate surface quality.

A possible solution uses locally-selective exposure and scrolling, whereby sub-areas of the surface are exposed quasi-continuously. This puts the highest demands on the accuracy of the 3-axes system which moves the resin bath and the exposure; the axis movements must run absolutely synchronized and the positioning of the DLP exposure may deviate by no more than half a pixel size in order to avoid blurred edges.

Prototypes and small series production of microfluidic chips are urgently needed for the further development of Point-of-Care-Diagnostics. The research facility currently being developed by Fraunhofer ILT, LightFab and BUSCH Microsystems, is a contribution to making this further development more economical and therefore accessible to significantly more users.

The requirements are being currently specified and we are drawing up the facility concept. We can soon start with the construction of the facility. The first sample parts should be available in the first half of 2023, to not only work through various theoretical approaches to exposure but also to try them out in practice.

The research project has just started. We ourselves are very excited about its further development and the results it will produce in the next two years and of course we will keep you updated here in the Competence Center.